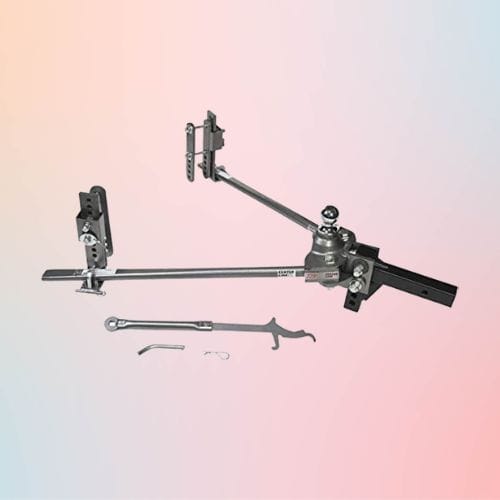

Why Do You Need a Weight Distribution Hitch?

Hey there, road warrior! Ever hitched up a heavy trailer and felt your truck’s front wheels getting scary light? Or had your rig sway like a drunk karaoke singer on a highway curve? Weight distribution hitches aren’t just fancy add-ons—they’re your secret weapon for keeping you and your cargo safe. Let’s break it down.

Why bother? Imagine your trailer’s tongue weight is like that one friend who always hogs the couch. Without a weight distribution hitch, all that weight crushes your truck’s rear axle, lifting the front tires—yikes. Steering feels mushy, brakes turn into “suggestions,” and your tires wear out faster than cheap sneakers. 10-15% of your trailer’s total weight should be on the tongue—but only if it’s spread evenly. That’s where this hitch shines. It’s like a bouncer at a club, making sure the load’s balanced across all axles.

Sway? Fishtailing? Sucks, right? Picture this: Your trailer starts dancing sideways on the highway. White-knuckle grip, panic sweat—no thanks. A weight distribution hitch locks things down. It redistributes weight forward, so your truck and trailer move as one unit. No more “tail wagging the dog” moments. How’s that for peace of mind?

Bounce reduction is the unsung hero here. Hauling a camper or boat? Without the right hitch, every bump feels like a carnival ride gone wrong. Your coffee spills, your dog barfs, and your patience? Gone. These hitches cut the chaos, giving you a smoother ride. Legit game-changer for long hauls.

But wait—what about setup? Chill, it’s not rocket science. Adjust the hitch’s spring bars to match your load. Too much tongue weight? Tighten ‘em. Too little? Loosen up. Most hitches work with trailers up to 14,000 pounds, but always check your truck’s manual. Overloading? Nice try. Your suspension will tap out faster than a toddler at naptime.

Safety isn’t optional. Think of this hitch as your insurance policy. It’s not just your rig you’re protecting—it’s the family in the minivan next to you. Proper weight distribution means better braking, sharper steering, and tires that last. Skip it, and you’re rolling the dice with every mile.

Still not convinced? Picture towing a trailer that’s 20% heavier than your truck’s rating. Without a weight distribution hitch, you’re basically driving a seesaw. Add crosswinds or a sudden lane change? Recipe for disaster. Spend the extra cash—it’s cheaper than a tow truck and a hospital bill.

So next time you hitch up, ask yourself: Is my setup sketchy or solid? Your answer could save your rig—and your rep as the “responsible” one in the group. 🚛💨 (Psst—need a hitch recommendation? Slide into our DMs. We’ve got your back.)

Related Topics: Hitch Cargo Carriers and Popular Hitch Cargo Carriers With Ramp

Quick-Pick List Of 9 Weight Distribution Hitch For Vans, Sedans, and Trucks

Image | Brand | Item Weight | Material | Finish Type | Loading Capacity | Links |

|---|---|---|---|---|---|---|

| CURT | 100 Pounds | Carbon Steel | Powder Coated | 10,000 to 14,000 lbs | |

| CURT | 94 Pounds | Carbon Steel | TEXTURED BLACK POWDER COAT | 8,000 to 10,000 lbs. GTW and 800 to 1,000 lbs. TW | |

| CAMCO | 30 Pounds | Alloy Steel | Powder Coated | Maximum Tongue Weight: 1,200 lb. Maximum Gross Weight Rating: 12,000 lb | |

| VEVOR | 84 Pounds | Alloy Steel | Powder Coated | 1000 lbs | |

| HUSKY TOWING | 116 Pounds | Alloy Steel | Powder Coated | 12,000lbs | |

| CURT | 100 Pounds | Carbon Steel | Powder Coated | 8,000 to 10,000 lbs | |

| Equal-i-zer | 52.8 pounds | Alloy Steel | Painted | Maximum gross towing weight: 14,000 lbs | |

| CURT | 12.25 Pounds | Carbon Steel | Durable black powder coat finish | / | |

| CURT | 25 Pounds | Carbon Steel | Powder Coated | / |

Detail of 9 Weight Distribution Hitch Components For Cars

CURT 17063 Round Bar Weight Distribution Hitch

Hey road warrior! Ever white-knuckled the wheel while your trailer sways like a drunk karaoke singer? Or felt your truck’s front end get scary light on hills? The CURT 17063 Round Bar Hitch is here to save your sanity—and your cargo. Let’s break down why this beast is a game-changer.

Weight distribution? Legit magic. Imagine your trailer’s tongue weight isn’t just crushing your rear axle—it’s shared evenly across your truck and trailer. No more saggy butt suspension or front tires barely touching pavement. This hitch spreads the load like butter, so steering stays crisp, brakes actually work, and your tires don’t wear out faster than a TikTok trend. Hauling a tiny utility trailer or a 14,000-pound camper? Doesn’t matter. CURT’s got your back.

Carefully read the Official Installation Manual to increase accuracy during the process of installation

Sway control? Built-in. Picture this: You’re cruising the highway at 65mph, and a semi blasts past. Without CURT’s sway bar, your trailer fishtails like a wet noodle. Sucks, right? But with this hitch, that integrated stabilizer locks your rig straight, like a bouncer at a club. Tight curves? Crosswinds? Whatever. You stay in control, not the trailer.

Versatility? Total flex. Camping trips, construction gear, or your buddy’s “borrowed forever” boat—this hitch handles it all. The round bar design adjusts faster than your mood on a Monday morning. Need to switch between trailers? No big deal. Loosen a few bolts, tweak the tension, and boom—you’re ready to roll.

Setup? Chill. CURT includes idiot-proof instructions (we’ve all needed those). The spring bars clip on smooth, and the sway control? Just crank the knob until your trailer stops acting like a toddler. Pro tip: Grease the fittings—trust us. Your future self will high-five you when it doesn’t squeak like a haunted house.

Still towing with a basic hitch? Give me a break. The CURT 17063 isn’t an upgrade—it’s a safety essential. Ditch the white-knuckle drives and start hauling like a pro. 🚛💨 (Pssst—tag us when you install it. We’ll hype your setup!)

Hey road warrior! Ever felt your hitch tap out mid-haul? The CURT 17063 Round Bar Hitch laughs at 10,000 to 14,000 pounds of trailer weight—for real. Tongue weight? 1,000 to 1,400 pounds? No big deal. Built with a heavy-duty head and forged steel bars, this thing’s tougher than your uncle’s ’90s pickup. Hauling a camper, boat, or that friend’s “borrowed forever” gear? Legit handles it all.

Versatility? Plug-and-play vibes. The 2-inch shank fits any standard receiver—no cussing at mismatched parts. Need a deep-drop setup? Swap it faster than your mood on a Monday. Oh, and it comes with a 2-5/16-inch ball—no last-minute Walmart runs. How’s that for convenience?

Durability? Please. The carbide black powder coat laughs off rust, salt, and your kid’s “helpful” car wash. Rain? Snow? Mud? Whatever. This hitch ages like a fine bourbon—stays sharp, not crusty.

Still using a hitch that flakes like a bad Tinder date? Give me a break. The CURT 17063 isn’t just sturdy—it’s overbuilt on purpose. Your rig’s begging for an upgrade that actually works. 🚛💨 (Tag us when you tow—we’ll hype your setup!)

Hey road warrior! Tired of hitches that squeak like a haunted house? The CURT 17063’s got two grease zerks right on the head—no yoga poses required. Pump in some grease, and boom—smooth, silent towing. Less grunt work, more miles. How’s that for low-maintenance bliss?

Sway control? Built-in. Ever had your trailer fishtail like a toddler on a sugar rush? This hitch’s sway bar locks it down. Highways, backroads, or that sketchy mountain pass—you stay in charge. Crosswinds? Whatever.

Durability? Legit overkill. That rust-proof carbide coating laughs off salt, mud, and your kid’s “helpful” car wash mishaps. Rain? Snow? No big deal. This hitch ages like a vintage leather jacket—cooler with time.

Versatility? Hauling a 12,000-pound camper or a tiny utility trailer? Doesn’t matter. Adjust the tension, swap the shank, and boom—ready for action. Camping trips, job sites, or hauling your buddy’s “project car”? Chill, it’s covered.

Still rolling with a basic hitch that sways like a pendulum? Give me a break. The CURT 17063 isn’t just reliable—it’s your ticket to stress-free towing. Ditch the white-knuckle drives and start trusting your rig. 🚛✨ (Tag us when you hit the road—we’ll hype your haul!)

CURT 17601 TruTrack 2P Weight Distribution Hitch

When it comes to towing trailers, safety is paramount. The CURT 17601 TruTrack 2P Weight Distribution Hitch is a versatile and reliable solution that ensures a smooth and secure towing experience. With its integrated sway control and precise weight distribution capabilities, this hitch offers peace of mind for all your towing needs.

Hey road warrior! Ever white-knuckled the wheel while your trailer sways like a drunk karaoke singer? The CURT 17601 TruTrack 2P is here to save your sanity—and your cargo. With integrated sway control, it’s like having a bouncer for your trailer, locking it down at two points to stop fishtails dead. Hauling a camper or boat? No sweat. This hitch laughs at 8,000 to 10,000 pounds of trailer weight and 800 to 1,000 pounds of tongue weight—legit overbuilt.

Weight distribution? Precision mode activated. The 7-hole shank lets you dial in tension like a pro—no more guessing games. Paired with heavy-duty round spring bars, it balances your load so your truck doesn’t sag like a tired bulldog. Old-school hitches? Nice try. This one’s the Swiss Army knife of towing.

Setup? Chill. The tilting head lets you tweak angles without dismantling the whole rig. Bolt it on, adjust the tension, and boom—you’re road-ready. No grunt work, no cussing at vague instructions. Pro tip: Grease the fittings—your future self will high-five you.

Durability? Built like a tank’s handshake. The fabricated steel head scoffs at potholes, while the carbide black powder coat fights rust like it’s personal. Rain, snow, or your kid’s enthusiastic car wash? Whatever. This hitch ages like a vintage leather jacket—better with time.

Sway control? Game-changer. Crosswinds on the highway? Tight mountain curves? The TruTrack’s fixed brackets keep your trailer in line, so you steer—not sweat. Still using hitches that sway like a pendulum? Give me a break.

Versatility? Hauling a tiny utility trailer or a 10k-pound beast? Adjust the shank, swap the ball, and go. Camping trips, job sites, or rescuing your buddy’s “project car”? Chill, it’s covered.

Corrosion-resistant? Obviously. That powder coat isn’t just for looks—it’s armor against salt, mud, and that puddle you “didn’t see.” Rust? Nice try. This hitch stays shiny while your truck collects dirt like a trophy.

Grease fittings? Two zerks right on the head—no yoga needed. Keep ’em lubed, and your hitch purrs like a kitten. Squeaks? Gone. Sudden stops? Silent. Maintenance? Five minutes, tops.

Still rolling with a hitch that’s all sway, no stay? The TruTrack isn’t just an upgrade—it’s insurance against chaos. Ditch the stress, save your tires, and actually enjoy the drive. 🚛💨 (Tag us when you tow—we’ll hype your setup!)

How to install the CURT 17601 TruTrack 2P Weight Distribution Hitch

Hey road warrior! Ever hitched up a trailer only to feel your truck’s rear end sagging like a deflated balloon? Or white-knuckled the wheel when your rig starts swaying like a pendulum on caffeine? The CURT 17601 TruTrack 2P isn’t just a hitch—it’s your sanity saver. This bad boy doesn’t just balance your load—it owns it, spreading weight evenly so your truck doesn’t wobble like a toddler on a balance beam. Steering stays crisp, brakes actually work, and your tires won’t wear out faster than your patience in traffic.

Here’s the deal: Without a weight distribution hitch, your trailer’s tongue weight crushes your rear axle, lifting the front tires like they’re auditioning for Cirque du Soleil. The TruTrack 2P? It’s like a gym buddy for your truck—redistributing the load so your suspension doesn’t tap out. Adjustable spring bars and a 7-hole shank let you dial in tension like a pro—no PhD required. Still using a basic hitch? Give me a break. This thing’s built to hustle, handling trailers up to 10,000 pounds without breaking a sweat.

Ready to install? Chill, it’s easier than assembling IKEA furniture. Bolt the hitch head into your receiver, snap on the spring bars, and tweak the tension until your rig sits level. The tilting head lets you adjust angles without dismantling everything—no cussing required. Pro tip: Grease the fittings before you hit the road. Your future self will thank you when the hitch purrs like a kitten, not screeches like a haunted house. Tag us in your setup pics—we’ll hype your towing glow-up! 🚛✨

Official User Manual can help you prepare enough knowledge before a successful installation.

Step 1: Slide the Shank In

What’s up, truck fam? Start by sliding the adjustable shank into your truck’s receiver tube—no grunt work needed. Lock it down with the hitch pin and clip. Got a lifted rig? No big deal—flip the shank upside down if you need extra height. Just make sure you’ve got enough clearance underneath. Scraping your hitch on driveways? Sucks. Mark that spot with a Sharpie so you don’t forget.

Step 2: Torque the Ball Like a Pro

Next, slap the trailer ball onto the head and crank it down to 450 ft-lbs—yeah, that’s specific. Use the lock washer and nut to keep it from wobbling like a loose tooth. Pro tip: Borrow a torque wrench from your neighbor—they’ll never notice. Tighten it until your arms scream “uncle,” then double-check. Loose balls? Not cool.

Step 3: Align the Head & Bolt It Down

Slide the head onto the shank and move it up or down until the bolt holes match your target height. Too high? Too low? Mark the sweet spot with a Sharpie—chill, it’s not permanent. Thread the 3/4-inch bolt through the bottom hole, add the cone-shaped washer, and tilt the head forward until the ball’s dead straight or slightly leaning back. Crooked? Tweaking the set screws. Legit easy.

Step 4: Add the Top Bolt & Finger-Tighten

Grab another 3/4-inch bolt and washer, then slide it through the top hole. Pop on the washers and screw the lock nuts on by hand—no power tools yet. Finger-tighten everything so it’s snug but not stuck. Why? Because you’ll need to adjust things later. Test the ball height by sitting in the driver’s seat—truck level? Nice. If not, tweak the shank and repeat. Boom—ready to roll. 🚛💨 (Tag us in your setup—we’ll hype your towing glow-up!)

Step 5: Tighten That Top Bolt

Alright, road warrior—time to crank down the ¾-inch bolt at the top. This bad boy locks the head to the shank, so don’t skip this. Use a wrench to snug it up, but chill—you’ll fully tighten everything later. Just get it tight enough to hold while you finish the job. Pro tip: Double-check the ball’s tilt—slightly backward is golden.

Step 6: Grease & Click Those Spring Bars

Slather heavy grease on the ends of the spring bars—no skimping. Shove each bar up into the hitch head until you hear a click. That sound? Music. Need to remove them later? Push up gently and yank the pin out. Warning: Grease hands = messy steering wheel. You’ve been warned.

Step 7: Connect the Trailer

Lower the trailer tongue with the jack until the coupler kisses the ball. Line it up, snap the latch shut, but keep some weight on the jack. Why? Because trailers love to wobble when you least expect it. Don’t drop all the weight yet—save the sweaty-palm moments for mountain roads.

Step 8: Mount the Support Brackets

Grab a marker and draw lines 4 inches back from the trailer’s front corners—that’s your bracket zone. Slide the carriage bolt through the bracket holes, add a washer, and hand-tighten the lock nuts. Don’t fully tighten yet—you’ll adjust these later. Hook the spring bars into the brackets, then step back—your rig’s almost ready to roll. Check if the truck sits level. Crooked? Adjust the tension. Boom—towing glory awaits. 🛠️🚚 (Tag us—we’ll hype your setup!)

Step 9: Lift That Trailer Like a Pro

What’s up, tow boss? Crank the tongue jack to lift the trailer’s front and your truck’s rear by 3 inches. Why? To get your truck’s saggy butt back to its original height—no more dragging. Check the clearance under your hitch—scraping driveways sucks. Keep the jack supporting some weight so the trailer doesn’t wobble like a Jenga tower. Pro tip: Measure your truck’s bumper height before and after—no guessing games.

Step 10: Lock Down Those Spring Bars

Once your rig’s level, slap those spring bars into their brackets from Step 7. Push ‘em in until they click—that’s the sound of success. Wiggle ‘em to make sure they’re locked, not just halfway there. Loose bars? Big nope. They’ll bounce like a trampoline on the highway. Warning: Don’t skip the grease—squeaky bars are the worst.

Step 11: Install the L-Support Bracket

Slide the L-support bracket between the two you already mounted—follow the diagram like it’s a treasure map. Line it up under the trailer’s A-frame, but keep at least 4 inches of clearance underneath. Why? So you don’t turn speed bumps into hitch grinders. Bolt it in with a carriage bolt and tighten the nut to 25 ft-lbs—borrow that torque wrench again. Pro tip: Hold the bracket steady with one hand—multitasking for the win.

Step 12: Lift the Spring Bars for Perfect Tension

Pop the spring bars out of the A-frame—gentle, they’re not piñatas. Slide the lift bar into the L-bracket’s slot—it’s like LEGO for adults. Crank the lift bar to raise the spring bars until they’re snug, not banjo-string tight. This spreads the weight evenly so your truck doesn’t ride like a seesaw. Check the diagram—unless you want to redo this step. Boom—you’re basically a towing wizard now. 🚛✨ (Tag us—we’ll repost your setup!)

Step 13: Lock the Spring Bars to the L-Bracket

What’s up, road warrior? Hook the lift bar into the L-bracket and crank it down until the spring bars sit snug on the bracket. No half-stepping—this is where the magic happens. Rotate the lift bar to adjust tension—think of it like tuning a guitar string. Once the bars are tight, yank the lift bar out—easy does it. Pop in the retainer clip and cotter pin to lock everything down. Skipping this? Your bars could bail mid-drive. Not cool.

Step 14: Check Your Truck’s Height & Tweak the Angle

Time to play detective. Lower the tongue jack so the hitch takes the weight. Does your truck sag in the back? Ugh. Measure the front and rear bumper heights. If the front’s higher, tweak the set screws on the hitch head until the truck sits level. Pro tip: The spring bars should be almost horizontal—if they’re slanted, crank the screws more. Still uneven? Repeat until your rig looks Instagram-ready.

Adjusting the Head Angle

Hop out and eyeball the hitch head. Is the ball tilted slightly back? Good. If it’s leaning forward, loosen the set screws and tilt the head until it’s just right. Tighten the screws back down—don’t strip ‘em. Test drive around the block. Feel any sway? Nope? You’re golden. Yes? Recheck the tension. Annoying, but cheaper than a tow truck.

Final Checks Before Hitting the Road

Walk around the rig like a paranoid parent. Are the spring bars locked? Cotter pins in place? Grease spots covered? Good. Snap a pic for the ‘gram—you’ve earned it. Now, go haul that trailer like a boss. Tag us—we’ll hype your towing glow-up! 🚛💥 (And hey, no trailer tantrums allowed.)

Step 15: Crank Those Bolts Like a Pro

Alright, road warrior—final stretch! Grab your torque wrench and tighten all ¾-inch bolts to 200 ft-lbs. Yeah, that’s specific—no eyeballing. The set screws? Hit ’em with 50 ft-lbs—not too tight, not too loose. Skipping this? Your hitch could rattle loose mid-haul, and nobody wants to chase bolts down the highway. Pro tip: Label each bolt with a Sharpie once tightened—no second-guessing later.

Double-check every nut and washer. Loose hardware? Big nope. This isn’t IKEA furniture—your safety depends on it. Still unsure? Wiggle the hitch head. If it moves more than your ex’s loyalty, re-torque. For real? For real.

Done? Almost. Lower the trailer jack completely and let the truck settle. Hop out—does your rig sit level? Spring bars horizontal? Ball slightly tilted back? Boom—you’ve nailed it. Take a victory lap around the block. Feel any sway? Nope? You’re golden. Yes? Recheck the tension or call a pro—no shame.

Remember: If your gut says “this feels off,” listen. Towing’s not a DIY daredevil sport. A quick pro check costs less than a roadside disaster. Tag us in your setup pics—we’ll hype your towing glow-up! 🚛✨ (Now go haul like you own the road.)

Camco Eaz-Lift Elite 1000lb Weight Distributing Hitch: Elevating the Standards of Your Trailer Travel Experience

Hey road warrior! Tired of trailers that sway like a tipsy karaoke singer? The Camco Eaz-Lift Elite 1000lb Hitch isn’t just another gadget—it’s your sanity saver. Built from alloy steel (aka indestructible), this bad boy laughs at heavy loads while weighing just 30 pounds—lighter than your gym bag. That powder-coated finish? Legit armor against rust and road salt. Rain, mud, or your kid’s “helpful” car wash? Whatever.

Think about it: Why stress over fishtailing trailers or saggy truck butts? This hitch distributes weight like a pro, keeping your rig level and stable. Hauling a camper, boat, or your buddy’s “borrowed forever” gear? No sweat. The Eaz-Lift’s like a Swiss Army knife—simple, reliable, and built to last. Plus, setup’s a breeze—no PhD required.

Still using hitches that rust faster than last year’s gym resolutions? Give me a break. The Camco’s 1,000-pound capacity handles your grind, while the sleek design won’t cramp your truck’s style. For real? Test drive it. Your white-knuckle days are over. 🚛💥 (Tag us in your setup—we’ll hype your towing glow-up!)

Sway Control That Actually Works

Let’s be real—trailer sway sucks. Crosswinds, semis blasting past, or sudden lane changes? The Camco Eaz-Lift Elite Hitch slaps sway in the face with its adjustable sway control. Crank the clamp tighter for highways, loosen it for backroads—you’re the boss. No more white-knuckle moments or praying your trailer doesn’t fishtail into oblivion. For real? This hitch’s like a bouncer for your rig, keeping everything in line.

What’s in the Box? The kit’s stacked: round bar hitch, sway control, and a 2-5/16-inch ball that locks your trailer down like Fort Knox. The round bar? Genius. It spreads weight evenly, so your truck’s rear axle isn’t crying uncle. Hauling a 12,000-pound trailer with 1,200 pounds on the tongue? No big deal. This setup’s the Swiss Army knife of towing—simple, reliable, and ready for anything.

Adjustments? Chill. Loosen the clamp, tweak the tension, and tighten it back up—no grunt work. Stuck in a storm? Adjust on the fly without pulling over. Lost the manual? The design’s so intuitive, you’ll feel like a towing sensei. Pro tip: Grease the moving parts—squeaks are for horror movies, not hitches.

Built Like a Tank, Light as a Feather Weighing just 30 pounds, this hitch laughs at heavy loads while wearing rust-proof armor (aka powder coat). Rain, salt, or your kid’s “helpful” car wash? Whatever. Still using hitches that rust faster than your gym motivation? Give me a break. Camco’s got your back—durable, sleek, and no-nonsense.

Bottom Line? Ditch the stress. This hitch isn’t an accessory—it’s insurance. Tag us when you hit the road—we’ll hype your towing glow-up! 🚛💥 (Your trailer’s about to behave.)

Why the Camco Eaz-Lift Elite Hitch Owns the Competition

Let’s get real—installing hitches sucks. Missing bolts, confusing instructions, that one trip to Home Depot… Not here. The Camco Eaz-Lift comes pre-assembled—ball, sway control, U-bolts, chains—already torqued and ready. Unbox it, bolt it on, and boom—you’re towing in 15 minutes. Skipped steps? Nope. This thing’s plug-and-play for adults.

What’s in the Box? Everything. The 2-5/16-inch hitch ball? Mounted. Sway control? Attached. Spring bars with chains? Factory-installed. Even the hardware’s included—no scavenger hunts for nuts or washers. Lost a piece? Impossible. Camco’s like that friend who packs your lunch—no leftovers.

Sway Control That Doesn’t Half-A It*

Crosswinds? Semis? Whatever. Adjust the sway tension with a clamp—no tools, no sweat. Tighten it for highways, loosen it for backroads. Your trailer stays straight, like a kid bribed with candy. Still white-knuckling? Give me a break.

Weight Distribution So Smooth, It’s Chef’s Kiss

The round bars spread your trailer’s weight like butter on toast. No saggy truck butt, no front wheels floating like they’re on vacation. Hauling a camper or a 12,000-pound load? Legit handles it. Plus, the powder-coated finish laughs at rust, mud, and your neighbor’s judgy side-eye.

Bottom Line: Ditch the DIY nightmares. This hitch’s idiot-proof, overbuilt, and ready to roll. Tag us when you hit the road—we’ll hype your setup! 🚛💥 (Your trailer’s about to behave.)

Hey there! Tired of wrestling with confusing hitch setups that turn a simple job into a grunt fest? What if I told you the Camco Eaz-Lift Elite Hitch skips the headache by arriving mostly pre-built? Yep, stuff like the hitch ball, sway control, U-bolts, and chains come ready to roll—no digging through manuals for hours. Less time cursing at loose parts means more time hitting the road. And c’mon, who actually likes sorting through a million pieces? Not you.

Ever tried flipping a hitch part only to realize it’s not compatible the other way? Ugh, sucks, right? This thing’s got universal spring bars that work on either side—no big deal. For real, swap ‘em left or right without sweating the small stuff. How’s that for ditching old-school hitch headaches? Plus, this adaptability means it’s ready for whatever weird towing scenario life throws at you. Hauling a camper one day and a trailer full of gear the next? Legit.

Now, let’s talk toughness. The Elite Hitch isn’t just sturdy—it’s built like a tank with alloy steel and a powder-coated finish that laughs off rust and scratches. Oh, and that 1000lb capacity? Yeah, it’s a beast. Safety’s baked in too, with adjustable sway control so your load stays steady, even when roads get sketchy. Ever white-knuckled it worrying your gear might fishtail? Yeah, no thanks. This setup keeps you in command without the stress.

Worried about setup eating your whole weekend? Give me a break. The kit’s designed for quick installs—think “plug-and-play” but for hitches. Bolt it on, tweak the sway control, and bam—you’re road-ready. No PhD in engineering required. Why waste hours when you could be binge-watching your favorite show instead? Compromise on your weekend plans, sure—but never on safety or reliability. Trust this hitch to handle the heavy lifting so you can focus on the drive. Fair enough?

VEVOR Weight Distribution Hitch: Ensuring Safety and Stability during Trailer Towing

Hey, ever white-knuckled it while towing a heavy trailer? You know, that ugh moment when your camper sways or your boat feels like it’s dragging your truck sideways? For real, safety’s gotta be non-negotiable here. That’s where the VEVOR Weight Distribution Hitch steps in—no fancy jargon, just legit peace of mind. Whether you’re hauling gear for a weekend trip or moving serious cargo, this thing’s built to keep you steady. But how? Let’s break it down.

First off, let’s talk toughness. Tired of hitches that rust or bend after a few trips? Give me a break. The VEVOR’s made with high-grade hardened steel—think “tank vibes” but for your trailer. Rain, mud, or rough roads? Whatever. This hitch laughs it off. Plus, its 4-point swivel control system is like having a co-pilot for stability. Ever felt your trailer wobble like a shopping cart wheel? Sucks, right? Those four support brackets lock down sway at two spots, so your ride stays smooth even when the road’s not. And backing up? Chill. The swivel design makes turns feel like a breeze, not a wrestling match.

Now, about weight distribution. Ever notice how a heavy trailer makes your vehicle sag? No big deal here. The VEVOR spreads the load evenly between your rig and trailer axles, so your bumper isn’t screaming for mercy. Less strain = better control, especially on sketchy roads. Hauling a boat one day and a camper the next? Legit. This hitch adapts so you’re not stuck re-engineering your setup every time. How’s that for flexibility?

Oh, and let’s not forget the 4-point swivel control. Ever tried reversing a trailer and ended up in a grunt fest? This system’s like cheat codes for precision. Those fixed brackets don’t just fight sway—they make tight turns and parking feel almost easy. What if you could actually enjoy the drive instead of sweating every maneuver?

Bottom line? The VEVOR isn’t just about brute strength (though it’s got plenty). It’s about smart towing. Quick setup? Totally. Durable enough for cross-country hauls? Yep. And that 4-point system? Game-changer. Why settle for old-school hitches that leave you guessing? Fair enough? Next time you hitch up, make it something that’s got your back—not your nerves.

Alright, let’s get real—what’s the point of a hitch that looks tough but flakes like cheap paint after one rainy season? Sucks, right? The VEVOR Weight Distribution Hitch isn’t just built to last—it’s built to out-stubborn Mother Nature. Those straight plate brackets? They’re designed to slash wear on the spring bars, so you’re not stuck replacing parts every year. Plus, that twice-coated black electroplating isn’t just for show. It’s like armor against rust, salt, and whatever else the road throws at it. For real, this thing stays looking sharp even after years of hauling through mud, snow, or surprise monsoons. Who wants a hitch that ages like milk? Not you.

Speaking of setup—ever wasted a whole weekend wrestling with a hitch that needs a PhD to assemble? Give me a break. VEVOR gets it. Their hitch comes with a pry-bar tool that’s basically a cheat code for balancing the spring bars. No grunt work, no swearing at cryptic instructions—just click, adjust, and go. How’s that for saving your sanity? And guess what? You’ll be hooked up and rolling in way less time than it takes to binge-watch your favorite show. Legit. Why stress over setup when you could be chilling with a cold drink instead?

Oh, and let’s talk about that 4-point swivel control again. Ever tried backing up a trailer and felt like you’re herding cats? Nice try, but VEVOR’s system locks down sway so tight, your trailer behaves like it’s on rails. Those fixed brackets? They’re like bouncers for wobble—shutting it down at two key spots so you can steer with confidence, even on winding roads. Tight turns? Reversing into a sketchy campsite? No big deal. It’s like the hitch reads your mind. What if towing actually felt… easy?

Bottom line—this isn’t just another hitch. It’s your wingman for every haul. Durable enough to laugh off rust, smart enough to handle weight distribution like a pro, and so easy to set up, you’ll wonder why hitches ever needed to be complicated. Fair enough? Next time you’re gearing up for a trip, skip the old-school headaches. With VEVOR, you’re not just towing—you’re owning the road. Chill, relax, and let the hitch do the heavy lifting.

Center Line TS Weight Distribution Hitch

Hey, ever felt your trailer sway like a tipsy friend on a road trip? Ugh, sucks, right? Safety’s no joke when you’re hauling, and the Husky Towing Center Line TS Hitch gets it. This bad boy doesn’t just balance weight—it kills sway without needing extra gadgets. What if you could skip the headache of bolting on separate sway control? No big deal here—it’s all built-in. Less clutter, fewer parts to lose, and way more cash left in your pocket. Legit.

Now, let’s talk setup. Ever wrestled with a hitch that feels like a puzzle missing half its pieces? Give me a break. The Center Line TS throws you a bone with its easy-adjust brackets. Pop the handle on, hook up the bars, and boom—you’re done. How’s that for saving your Saturday? No grunt work, no cussing at the manual. Just chill and bolt it on. Plus, removing it’s just as smooth. For real, why make life harder than it needs to be?

Oh, and guess what? This hitch is lighter than your ex’s excuses. Seriously. We’re talking way less heft than most hitches out there. Why lug around a boat anchor when you can sling this thing around like a gym bag? Your back will thank you when you’re not sweating bullets trying to lift it into place. Fair enough?

Durability? Pfft. This ain’t some flimsy tin can. The Center Line TS is built with forged 1035 steel—translation: it’s tougher than a two-dollar steak. Rain, rust, or rough roads? Whatever. It’ll outlast your truck’s warranty. Hauling heavy loads? Totally. This thing’s got the muscle to handle it without breaking a sweat. How’s that for peace of mind?

And hey, let’s not forget the forged steel components. They’re not just strong—they’re ”survive-a-zombie-apocalypse” strong. Think long-term reliability, zero wobble, and zero drama. Ever had a hitch wear out mid-trip? Nice try, but this one’s built to stick around.

Bottom line—this hitch isn’t just a tool. It’s your road-trip wingman. Combines sway control and weight distribution so seamlessly, you’ll wonder why other hitches even bother. Chill setup, lightweight hustle, and durability that’s basically old school cool. Next time you hitch up, make it something that’s got your back—not your nerves. Fair enough?

Alright, let’s cut to the chase. Ever been stuck with a hitch that’s tough but still lets your trailer dance like it’s at a rave? Nice try, but the Husky Center Line TS isn’t just durable—it’s a straight-up performance beast. That TS tech? It sniffs out sway way faster than other hitches, so you’re not white-knuckling the wheel when things get wobbly. How’s that for staying chill while towing? Plus, it’s quieter than your nosy neighbor during a nap. No clanks, no rattles—just smooth, silent control. For real, who needs extra noise when the road’s already chaotic?

Oh, and let’s talk about the pre-installed hitch ball. Ever spent an hour squinting at torque specs only to still question if it’s tight enough? Give me a break. This ball comes factory-set, so you’re not playing mechanic. Slap it on, hook up, and go. Boom. Time saved = more time for snacks. Legit. Why fuss with tools when you could be halfway to your campsite instead?

Speaking of noise—ever had a hitch that sounds like a skeleton crew banging pots? Sucks, right? The Center Line TS flips the script. Its quiet operation is like swapping a rusty door hinge for a silent ninja. Hauling a trailer shouldn’t feel like dragging a metal orchestra. What if you could actually hear your playlist over the road noise? Yeah, this hitch gets it.

Performance-wise, this thing’s a mind reader. The TS tech doesn’t just react—it anticipates sway. Sudden gusts? Sharp turns? No big deal. It nips wobble in the bud so your rig stays planted. Ever felt that panic when your trailer starts fishtailing? Ugh, worst feeling. With this hitch, it’s like having a co-pilot who’s got lightning reflexes. How’s that for confidence?

And hey, let’s not skip the wallet-friendly perks. Lower install time means fewer labor costs if you’re not DIY-ing it. Plus, no buying extra sway bars or gadgets. Old-school hitches nickel-and-dime you—this one’s all-inclusive. Fair enough? Save your cash for gas station coffee and roadside pies.

Bottom line? Whether you’re hauling a camper, boat, or work trailer, the Center Line TS doesn’t just “work.” It owns the job. Durable? Totally. Quiet? Yep. Easy to slap on? You bet. Next time you hitch up, skip the drama and grab something that’s as over-prepared as your aunt’s holiday dinner spread. Chill out, crank the tunes, and let the hitch handle the grunt work. Fair enough?

CURT 17062 Round Bar Weight Distribution Hitch

Hey, ever felt like your trailer’s bouncing around like a shopping cart with a busted wheel? Ugh, sucks, right? The CURT 17062 Round Bar Weight Distribution Hitch is here to fix that vibe. It’s not just about leveling your load—it’s about smoothing out the ride so your truck and trailer feel like they’re actually working together. Think less fishtailing, more “chill cruise.” How’s that for ditching white-knuckle drives? And yeah, it’s legit built to spread that tongue weight evenly, so your rig isn’t sagging like it’s got the Monday blues.

Now, let’s talk grease—because nobody’s got time for squeaky hitches. The 17062’s got this slick continuous lube system with two grease zerks right where you need ‘em. For real, you ever spent a weekend crawling under your trailer with a grease gun? Give me a break. This thing lets you zap some grease in quick, keeping things quiet and friction-free. No more grinding noises that make your passengers side-eye you. What if your hitch could just… stay lubed? No big deal here—this system’s like a self-care routine for your gear.

Oh, and maintenance? Pfft. The CURT’s design cuts the drama. Those zerks aren’t hidden like a bad Easter egg—they’re front and center. Pop the cap, grease it up, and bam—you’re back on the road without that old-school hassle. Ever had a hitch that’s louder than your kids in the backseat? Nice try. This one’s quieter than a ninja, so you can actually hear your playlist. Plus, less downtime means more time hauling gear, boats, or whatever’s on your agenda. Fair enough? Toss this hitch on and let it handle the grunt work while you enjoy the drive.

Alright, let’s get real—ever hauled a trailer that felt like it was fighting you every mile? The CURT 17062 isn’t just tough—it’s built like a tank. That fabricated head? It’s not some flimsy tin can. We’re talking forged steel spring bars that stretch 31-3/16 inches—long enough to handle heavy loads without breaking a sweat. For real, this hitch’s rated for 8,000 to 10,000 lbs. total trailer weight and 800 to 1,000 lbs. on the tongue. Hauling a camper, boat, or work gear? No big deal. It’s like having a bodyguard for your rig.

Now, versatility—ever tried forcing a square peg into a round hole? Sucks, right? The 17062’s 2-inch shank slides into any standard 2-inch receiver like it’s meant to be there. No grunt work, no jiggling—just a snug fit that stays put. Oh, and that pre-torqued 2-5/16-inch ball? It’s already locked and loaded, so you’re not playing mechanic with a torque wrench. Boom. Hook up and go. How’s that for cutting setup time in half?

Durability-wise, this hitch laughs at rust. That carbide black powder coat isn’t just for looks—it’s rust’s worst nightmare. Rain, road salt, or mud? Whatever. This finish shrugs it off like water on a duck. Ever had a hitch rust out after one season? Nice try. The 17062’s built to outlast your truck’s odometer.

Performance? Let’s talk smooth. The integrated lube system keeps things quiet—no squeaks, no groans. Those two grease zerks? They’re like cheat codes for maintenance. Ever wasted a weekend greasing every nook? Give me a break. A quick pump and you’re done. What if your hitch could practically maintain itself? Legit.

And don’t forget those forged steel spring bars. They’re not just strong—they’re ”survive-a-wilderness-roadtrip” strong. Off-road bumps? Sharp turns? Chill. This hitch keeps your trailer steady, so you’re not white-knuckling the wheel. How’s that for actually enjoying the drive?

Bottom line—the CURT 17062 isn’t just a hitch. It’s your hauling sidekick. Tough enough for heavy loads, smart enough to adapt, and slick enough to stay quiet. Why settle for old-school hitches that creak, rust, or wobble? Fair enough? Grab this one, and let your trailer tag along like it’s on rails. No drama, no stress—just you and the open road.

Equal-i-zer 4-point Sway Control Weight Distribution Hitch

Hey, ever white-knuckled the wheel when your trailer starts swaying like a pendulum on caffeine? Sucks, right? Safety’s non-negotiable when you’re hauling heavy, and the Equal-i-zer 4-Point Sway Control Hitch isn’t just good—it’s ”sleep-easy-while-towing” good. This isn’t your grandpa’s hitch. That 4-point sway control? It’s like having four bouncers shutting down trailer wobble before it even starts. For real, no other hitch throws shade at sway this hard. How’s that for keeping your rig straight on windy highways?

What makes this hitch a rockstar? Glad you asked. That alloy steel build isn’t just tough—it’s ”survive-a-hurricane” tough. Hauling a loaded camper or a boat that weighs as much as a small elephant? No big deal. The Equal-i-zer laughs at heavy loads while staying rust-free thanks to its slick painted finish. Ever had a hitch rust out after one salty winter? Nice try. This one’s got armor against corrosion, so it’ll look sharp longer than your last haircut.

And let’s talk about that sway control again—because it’s that good. Unlike hitches that need add-ons or voodoo magic, the Equal-i-zer’s 4-point system is built-in. Sudden gusts? Jerky lane changes? Chill. It nips sway in the bud, so you’re not fighting the wheel like it’s arm-wrestling you. What if towing felt… easy? Legit. Plus, setup’s a breeze—no PhD required. Hook it up, tighten a few bolts, and bam—you’re ready to roll.

Bottom line? This hitch isn’t just about brute strength (though it’s got plenty). It’s about smart towing. Quiet, rust-resistant, and with ninja-level sway control, it’s the wingman your trailer deserves. Why settle for sketchy old-school hitches that leave you sweating bullets? Fair enough? Grab the Equal-i-zer and turn those white-knuckle drives into ”crank-the-radio-and-relax” cruises. Your trailer’ll never know what hit it.

Alright, let’s cut to the chase. Ever felt your trailer trying to yank the wheel out of your hands on a sharp turn? Ugh, sucks, right? The Equal-i-zer’s weight-distributing design isn’t just fancy talk—it’s like magic for your rig. By spreading that tongue weight across all axles, it keeps your truck’s front end glued to the road. No more sagging bumper or shaky steering. For real, it’s like your trailer suddenly learned manners. How’s that for a smoother, safer ride?

Now, here’s the kicker: this hitch does double duty. While other hitches make you choose between sway control and weight balance, the Equal-i-zer slaps on both. Legit. Better steering? Check. Brakes that don’t feel like mush? Yep. And sway control that’s tighter than your grip on a coffee cup during a bumpy drive. What if you could actually relax instead of death-gripping the wheel? No big deal here. Sudden gusts or jerk drivers? Chill. This hitch’s got your back.

Versatility? Pfft. The Equal-i-zer’s like the Swiss Army knife of hitches. Hauling an RV one weekend and a boat the next? Whatever. Horse trailers, cargo haulers, even rigs with surge brakes—it’s all fair game. Ever tried switching hitches for different trailers? Give me a break. This one’s a universal fix, so you’re not juggling gear like a circus act. How’s that for simplifying your life?

And hey, setup’s a breeze. No grunt work or YouTube tutorials needed. Hook it up, adjust the tension, and bam—you’re road-ready. Ever wasted hours fiddling with chains and brackets? Nice try. This hitch’s ”plug-and-play” vibe means more time cruising, less time cussing. Fair enough? Ditch the stress and let the Equal-i-zer turn your hauls into ”windows-down, music-up” adventures. Your trailer’ll never know what hit it.

Alright, let’s get real. Ever worried your hitch can’t handle the load? The Equal-i-zer laughs at heavy hauls with a 14,000-pound max capacity—that’s like towing a small house. And the 2-5/16-inch ball? It’s the old-school standard for heavy-duty trailers, so you’re not stuck hunting for adapters. No big deal if you’re switching between rigs—this thing fits most trailers like a glove. How’s that for skipping the hardware store drama?

Setup? Pfft. Slide those sway brackets anywhere from 27” to 32” back from the coupler—no measuring tape PhD needed. The 36-inch spring bars (yeah, they’re 1-½ inches thick) lock down wobble like a bouncer at a club. And the 12-inch shank? It slips into almost any receiver, so you’re not playing “will it fit?” For real, it’s plug-and-play without the guesswork. Ever spent hours cursing at mismatched parts? Give me a break.

Height issues? Whatever. This hitch’s got 6 inches of trailer frame clearance, plus a 7-inch rise or 3-inch drop from the receiver. Hauling a low-slung boat or a tall horse trailer? Chill. Adjust it once, and you’re golden. What if your hitch actually adapted to your setup instead of the other way around? Legit.

Safety-wise, the 4-point sway control isn’t just hype. It’s like having four seatbelts for your trailer—nixing fishtails before they start. Sudden swerves? Crosswinds? No sweat. Your rig stays planted, so you’re not white-knuckling the wheel. Ever had a trailer try to drag you into the next lane? Sucks. This hitch slaps that nonsense down.

Bottom line? Whether you’re pulling an RV, a boat, or a trailer full of who-knows-what, the Equal-i-zer’s built to keep you steady. Ditch the grunt work and sketchy setups. Fair enough? Hook this bad boy up, crank the tunes, and drive like you own the road—because your family and gear deserve that kinda confidence.

CURT 17208 Replacement Weight Distribution Hitch Hookup Brackets

Hey, ever tried mounting spring bars on a trailer frame and felt like you’re solving a Rubik’s cube blindfolded? Sucks, right? The CURT 17208 Replacement Brackets cut through the chaos. These aren’t your grandpa’s clunky brackets—they’re built to lock those spring bars onto your trailer frame securely, so your setup stays rock-solid. For real, if safety’s your #1 priority (and it should be), these brackets are like the seatbelt for your towing gear. How’s that for peace of mind?

Got propane tanks or other junk hogging space on your trailer? Nice try, but the CURT 17208’s got your back. Their low-profile design slips around obstacles like LP tanks no big deal. No more yoga poses trying to hook up bars around bulky gear. What if mounting spring bars didn’t feel like a circus act? Legit. The angled shape gives you room to wrench things tight without skinned knuckles or grunt work. Campers, utility trailers, RVs—whatever you’re hauling, these brackets adapt like a champ.

And hey, let’s talk setup speed. The 17208’s geometry isn’t just smart—it’s ”why-didn’t-I-get-this-sooner?” smart. Slide the spring bars in, tighten up, and bam—you’re done. Ever wasted half a Saturday fumbling with finicky brackets? Give me a break. These things turn a headache into a 10-minute job. Chill vibes only, because ain’t nobody got time for towing drama. Fair enough? Grab these brackets and turn your trailer into a ”hook-up-and-go” machine.

Alright, let’s cut the fluff. Ever wrestled with spring bars that fight you like a cranky toddler? The CURT 17208 Brackets flip the script with their snap-up design. Just click the bars into place—no grunt work—and adjust tension up or down in seconds. Heavy trailer? No big deal. This feature slashes the elbow grease and dodges those “ouch” moments when your fingers get pinched. How’s that for keeping your knuckles intact while balancing your load? Legit.

Durability? Pfft. These brackets are built like a tank. The heavy-duty carbon steel laughs at rough roads, and those forged steel spring bars? They’re tougher than your neighbor’s opinions on lawn care. Plus, the carbide powder coat is rust’s worst nightmare. Rain, salt, mud—whatever. This finish sticks around longer than your in-laws’ holiday visit. Tired of brackets that rust out after one season? Give me a break.

Now, let’s talk fit. The 2″ x 2″ shank (or 2-½” if you’re fancy) adapts to any hitch or trailer setup. Trunnion bars? Round bars? Whatever. It’s like a universal remote for towing—no compatibility headaches. Ever tried forcing mismatched parts together? Sucks. These brackets slide in like butter, whether you’re hooking up a camper or a work trailer. What if your gear actually fit the first time?

Oh, and versatility? Chill. Swap trailers like you’re changing playlists. Need more height? Crank it up. Less? Drop it down. The CURT 17208’s adjustability is ”why-didn’t-I-buy-this-sooner?” energy. Fair enough? Ditch the old-school brackets that demand a PhD to install. Grab these, save your sanity, and get back to actual adventures—not hardware drama.

Hey, ever opened a towing kit only to realize you’re missing bolts or pins? Sucks, right? The CURT 17208 Brackets come with everything in the box—no scavenger hunt needed. Bolts, pins, even the instructions are clear enough for your cousin who still can’t program the TV remote. For real, slap these on your trailer frame, follow the step-by-step pics, and bam—you’re ready to roll. How’s that for skipping the “hold my beer” moments?

Let’s talk about that snap-up feature again. Ever spent 20 minutes wrestling spring bars only to have them pop loose? Give me a break. These brackets lock in with a satisfying click, so adjusting tension feels like flipping a switch. Heavy load? No big deal. Crank it up. Lighter trailer? Drop it down. It’s like having a volume knob for your towing setup. What if setup didn’t feel like manual labor? Legit.

Durability’s where these brackets flex. Heavy-duty carbon steel laughs at potholes, and that powder-coated finish? It’s rust’s worst nightmare. Rain, road salt, mud—whatever. These things stay looking sharp while your trailer’s out here living its best (messy) life. Tired of brackets that rust faster than a ’90s pickup? Nice try.

Compatibility? Chill. Whether you’re rocking a trunnion bar or a round bar hitch, the 2” or 2-½” shank adapts like a champ. Hauling a camper today and a utility trailer tomorrow? Whatever. Swap ‘em out faster than you skip ads on YouTube. Ever wished your gear could just… work? Fair enough? Grab these brackets and turn “stressful setup” into “why wasn’t this easier before?” Your trailer—and your sanity—will thank you.

CURT 17123 Replacement Weight Distribution Hitch Shank: The Perfect Solution for Safe and Secure Towing

Hey, ever white-knuckled it while towing, worried your hitch might bail on you mid-haul? Sucks, right? The CURT 17123 Shank is like the bouncer of your towing setup—built to keep things locked down, no matter how heavy the load. Made from carbon steel tougher than your gym buddy’s ego, this shank laughs at potholes, rough roads, and those ”oh crap” moments when your trailer decides to wobble. How’s that for peace of mind?

Compatibility? No big deal. Slap this shank into any CURT weight distribution hitch—it’s universal, baby. Got a 2-inch x 2-inch receiver? Perfect. The 5/8-inch hitch pin hole lines up like it’s meant to be there. Ever tried forcing mismatched parts like a bad Tinder date? Give me a break. This shank slides in smooth, no cussing required. What if swapping hitches felt as easy as changing a lightbulb? Legit.

Design-wise, CURT didn’t cut corners. The 17123’s built to last longer than your truck’s warranty. Rust? Whatever. The heavy-duty steel scoffs at rain, salt, and mud. And setup? Chill. Bolt it on, pin it down, and boom—you’re road-ready. Tired of hitch parts that rust or bend after one season? Nice try. This shank’s the ”set it and forget it” upgrade your rig’s been begging for. Fair enough?

Alright, let’s get real. Ever struggled to line up your hitch with a trailer that’s sitting too high or too low? Sucks, right? The CURT 17123 Shank throws you a lifeline with a 7-inch max drop and 10.5-inch rise—yeah, you read that right. Hauling a low-slung boat? Drop it down. Got a tall camper? Crank it up. No big deal. This shank’s like a chameleon, adapting to your trailer’s vibe. How’s that for ditching the “close enough” mindset?

But wait—there’s more. Those ¾-inch holes spaced ¼-inch apart? They’re like the belt notches of the towing world. Slide the head up or down to fine-tune your setup without needing a engineering degree. Ever wished adjusting your hitch was as easy as flipping a switch? Legit. Whether you’re hauling a tiny utility trailer or a beastly RV, this shank’s got the ”I got you” energy.

Now, let’s talk muscle. The forged steel spring bars aren’t just strong—they’re ”survive-a-zombie-apocalypse” strong. They spread the weight like butter on toast, keeping your rig steady even when the road gets sketchy. For real, swaying and fishtailing? Nice try. This shank slaps that nonsense down. What if your trailer actually stayed in its lane? Chill.

Durability? Pfft. The high-strength steel heads laugh at heavy loads and rough roads. Rust? Whatever. This thing’s built to outlast your truck’s warranty. And setup? Easy. Bolt it on, tweak the height, and bam—you’re ready to roll. Tired of hitches that quit after one season? Give me a break. The 17123’s here to stay. Fair enough? Grab it, hook up, and haul like you mean it—no sweat.

Alright, let’s cut through the jargon. Ever dealt with a hitch that rusts faster than a soda can in the rain? The CURT 17123 Shank slaps on a black powder coat finish that’s tougher than your gym playlist. Rain, road salt, mud—whatever. This finish laughs at corrosion, so your shank stays looking sharp and protects your rig like a bodyguard. How’s that for a hitch that ages like fine wine?

Size-wise, this shank’s 13-¼ inches tall and 11 inches long—compact enough to fit most trailers like your favorite jeans. Trunnion bars? Round bars? No big deal. It works with both, so you’re not stuck buying extra gear. Ever tried mixing-and-matching hitch parts? Sucks. This one’s plug-and-play, whether you’re hauling a tiny trailer or a monster RV. What if your gear just… worked? Legit.

Heads up: This shank’s not for light loads. For real, it’s built for heavy-duty towing—think campers, horse trailers, or gear that weighs as much as your in-laws’ opinions. Using it for a lightweight setup? Nice try. Safety first, folks. Always check your hitch’s weight rating—no one wants a “hold my beer” moment on the highway.

Durability? Pfft. The forged steel spring bars are ”survive-a-nuclear-winter” strong. They spread weight like butter, killing sway and fishtailing before they start. Ever white-knuckled it when your trailer swerves? Ugh. This shank keeps things tighter than your grip on a coffee cup during a pothole marathon.

Bottom line: Whether you’re towing cross-country or just across town, the 17123’s your wingman. Adjust the height in seconds, bolt it on, and chill. Tired of hitches that quit after one season? Give me a break. This one’s built to outlast your truck’s warranty. Fair enough? Hook it up, hit the road, and let CURT handle the grunt work. Your trailer’s got this.

At what weight should you use a weight-distribution hitch?

Hey, ever tried towing a heavy trailer and felt your truck’s backend sag like it’s doing a limbo? Sucks, right? That’s where a weight distribution hitch comes in clutch. If your trailer’s tipping the scales at 5,000 pounds or more, this gadget’s your new BFF. It spreads the load evenly across your rig’s axles, so your rear tires aren’t screaming for mercy. For real, it’s like giving your truck a balanced diet—no more stress on the back, better steering control, and way less “oh crap” swaying. What if towing heavy didn’t feel like wrestling a bear?

But wait—5,000 pounds isn’t a magic number for everyone. Got a beefy truck hauling a tiny camper? Maybe chill. Towing a boat that’s basically a small whale with a sedan? Yikes. Always check your vehicle’s manual and the hitch maker’s specs. Ever ignored instructions and ended up in a roadside nightmare? Nice try. Rules vary—some rigs need a hitch at 3,500 pounds, others at 6,000. Your neighbor’s setup? Whatever. Yours is unique.

Bottom line: Don’t wing it. Trust me, your truck’s manual and the hitch’s guidebook aren’t just paperweights. They’ll tell you exactly when to slap on that weight distribution hitch. No big deal—it takes five minutes to skim. Why risk fishtailing or fines when a little homework keeps your haul smooth and legal? Chill, follow the specs, and let the hitch be your wingman. Fair enough?

How much weight is transferred with a weight distribution hitch?

Alright, let’s break it down. Ever hooked up a trailer and felt your truck’s backend squat like it’s doing a deadlift?Weight distribution hitches are the unsung heroes here. They’re not just fancy metal—they’re designed to spread the trailer’s weight like butter across your rig’s axles. For real, this balance keeps your truck level, steering crisp, and wobble in check. What if your setup could handle heavy loads without the drama?

Here’s the scoop: these hitches shift 50% to 70% of the tongue weight to your front axle—the part that steers—so your rear tires aren’t crying uncle. The rest (30% to 50%) goes to the trailer axles. No big deal, right? This split stops your truck’s butt from sagging and saves your rear axle from early retirement. How’s that for a balanced diet?

But wait—it’s not one-size-fits-all. The exact split depends on your hitch model and how heavy your trailer’s tongue is. Ever tried guessing and ended up with a swaying mess? Nice try. Always check your hitch’s specs and your trailer’s weight. Legit, a little homework means less white-knuckling and more ”windows-down, music-up” vibes on the road. Fair enough?

What happens if the weight distribution hitch is too high?

Hey, ever cranked your weight distribution hitch too high and felt your truck’s front end get weirdly light? Sucks, right? When that hitch sits too tall, it’s like your front tires are ghosting you—losing grip and making steering feel like a shopping cart with a busted wheel. Hit a bump or a gust of wind? Good luck. Your rig gets twitchy, and suddenly you’re white-knuckling it just to stay in your lane. How’s that for a stress-filled road trip?

And let’s talk sway. Ever had your trailer start dancing sideways like it’s at a rave? An overadjusted hitch is basically an invite for that chaos. Sway doesn’t just rattle your nerves—it can yank you into a ”hold my coffee” emergency lane situation real quick. Plus, your suspension and tires? They’re taking a beating. For real, overloading them with uneven weight is like asking your gym buddy to deadlift a fridge solo—not cool. They’ll wear out faster than your patience in traffic.

Bottom line: Don’t eyeball it. Take five minutes to adjust that hitch properly. Level your rig, check the specs, and chill with the setup. What if a few tweaks could turn your hauls from sketchy to smooth? Legit. Your truck (and your sanity) will thank you. Fair enough?

What is the loading capacity of the weight-distributing hitch?

Hey, ever wondered why some hitches handle heavy loads like a boss while others crumble? It’s all about that load-bearing capacity—the max weight your hitch can actually handle without turning your rig into a wobbly mess. Think of it like this: a hitch’s strength depends on its design, build quality, and the tank-like materials it’s made from. Skimp here, and you’re asking for trouble. For real, would you trust a paperclip to hold up a cinderblock? Nice try.

Your truck’s GVWR (aka your rig’s max snack limit) plays big here. The higher your GVWR, the more your hitch can juggle. But push past that number? Sucks. Your steering gets mushy, sway kicks in, and suddenly you’re the star of a ”how NOT to tow” YouTube clip. What’s the point of a beefy hitch if it’s overloaded? No big deal—stick to the specs. Your hitch’s manual isn’t just a coaster; it’s your cheat sheet for safe hauls.

Here’s the kicker: even if your hitch says 10,000 pounds, your truck might tap out at 8,000. Legit. Always match your hitch’s capacity to your truck’s GVWR. Ever seen a lifted truck hauling a trailer that’s basically a small building? Chill. That rig’s dialed in. Overloading? That’s a long shot for disaster. Keep it balanced, check those ratings, and your setup’ll stay tighter than your grip on cold brew during a pothole marathon. Fair enough?

What is the disadvantage of a weight distribution hitch?

Alright, let’s keep it real. Ever tried hooking up a weight distribution hitch on a tight schedule? Sucks, right? Sure, these hitches work wonders for keeping your rig steady and sway-free—no argument there. But let’s be honest: they’re not exactly plug-and-play. You’re looking at extra steps—adjusting chains, tweaking tension, fiddling with bars—that turn a quick hookup into a ”where’s the manual?” marathon. What if you just wanna hit the road without a 30-minute setup? Nice try.

And the cost? Oof. These hitches aren’t just pricier upfront—they often need extra gear like sway bars or special shanks. Add installation fees if you’re not a DIY wizard, and suddenly your “budget-friendly” tow setup feels like a money pit. For real, dropping hundreds on a hitch plus parts? No big deal if you’re hauling daily, but totally overkill for the occasional camper trip. Ever felt like you’re paying for features you don’t even need?

Here’s the kicker: even if you nail the setup, not everyone wants the hassle. Weekend warriors hauling light loads might find these hitches way too extra. Why fuss with chains and tension when a basic hitch gets the job done? Plus, storing all those parts? Chill. Your garage isn’t a hardware store. Fair enough? Sometimes, simpler is smarter—even if it means skipping the “fancy” gear.

How much weight distribution do I need?

Alright, let’s break this down. Ever wondered why your car feels sketchy on sharp turns or your trailer sways like a pendulum? Weight distribution isn’t just a buzzword—it’s the secret sauce for keeping your ride steady. Think of it like loading a grocery bag: too much on one side, and boom—your milk’s on the floor. For cars, trucks, or hauling gear, nailing that balance means better control when you’re gunning it, slamming brakes, or taking curves like a pro. What’s the point of a beefy trailer if it fishtails? No big deal—until it is.

Now, hauling heavy stuff? Chill. You gotta spread that weight like peanut butter—evenly. Dump all the weight in the back? Sucks. Your front tires lose grip, steering gets sloppy, and suddenly you’re in a ”why’s my truck wobbling?!” situation. And hey, your vehicle’s type matters big time. A pickup handles weight way better than a sedan—duh. Off-roading in mud? Towing on highways? Each scenario flips the script on how you balance things. For real, would you load a dirt bike the same as a stack of plywood? Nice try.

Bottom line: There’s no one-size-fits-all answer. Start by asking, ”What am I hauling, and where?” Check your vehicle’s manual—yeah, that dusty book in the glovebox. When in doubt, chat with a pro. Ever seen a trailer flip because someone eyeballed the load? Legit. A little planning beats a roadside disaster. Fair enough? Get the balance right, and your rig’ll handle like a dream—no white-knuckling required.

What is the 60 40 trailer axle rule?

Hey, ever loaded your trailer and felt it sway like a pendulum on the highway? Sucks, right? That’s where the 60/40 rule swoops in like a superhero. Here’s the deal: 60% of your trailer’s total weight should sit over the axles, and 40% on the tongue or hitch. Think of it like balancing a grocery bag—too much in front, and your milk tips over. Nail this split, and your rig stays steady, steering stays crisp, and white-knuckle moments? Gone.

But ignore this ratio? Good luck. Load too much on the tongue (over 40%), and your truck’s backend squats like it’s doing a deadlift. Steering gets light, sway kicks in, and suddenly you’re fighting the wheel like it’s a rodeo bull. For real, trailers love to fishtail when they’re front-heavy. Skimp on tongue weight (under 40%)? Now the trailer’s wagging your truck like a tail. Tires wear unevenly, brakes struggle, and potholes feel like earthquakes. What’s the point of towing if it feels like a death trap?

Here’s the fix: Grab a bathroom scale (or hit a CAT scale) and measure your tongue weight. Aim for that golden 40%—close enough counts, but don’t eyeball it. Toss heavy gear just ahead of the axles, lighter stuff toward the back. Chill, it’s not rocket science. Test drive around the block before hitting the highway. Sway? Adjust. Sagging? Re-pack. Fair enough? Nail the 60/40 split, and your hauls go from ”please don’t kill me” to ”windows down, music up.” Your trailer—and your nerves—will thank you.

Our team is creating outdoor-gear relevant articles with passion. If our articles can help you to find the correct solutions for your questions, we will be happy about that. In the content creation process, we usually collect accurate and useful information online or offline to compile our content in an organized way. Consequently, we can guarantee that you can discover some expected answers to your questions. We appreciate your time on our site.